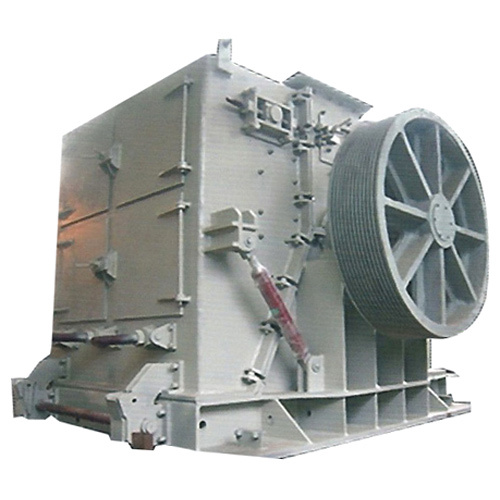

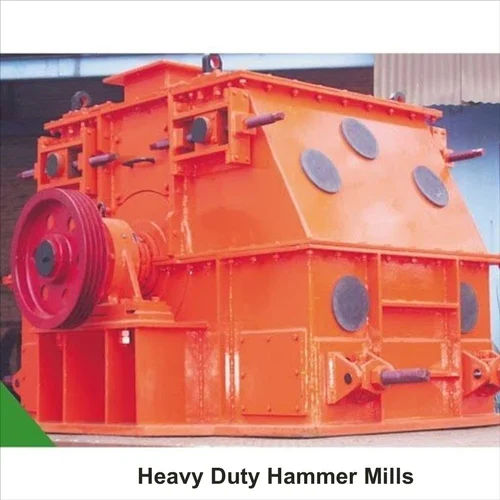

Hammer Mill

Product Details:

- Product Type Hammer Mill

- General Use Industrial

- Capacity 1000 T/hr

- Automatic Yes

- Voltage 280 Volt (v)

- Feature High Performance, High Efficiency, ECO Friendly, Low Noise, Lower Energy Consumption

- Warranty Standard

- Click to view more

Hammer Mill Price And Quantity

- 2200000 INR/Unit

- 1 Unit

Hammer Mill Product Specifications

- Hammer Mill

- Standard

- Yes

- 280 Volt (v)

- High Performance, High Efficiency, ECO Friendly, Low Noise, Lower Energy Consumption

- Industrial

- 1000 T/hr

Hammer Mill Trade Information

- Vadodara, Gujarat, India

- Cheque, Letter of Credit (L/C), Cash in Advance (CID), Cash Advance (CA), Telegraphic Transfer (T/T)

- 50 Unit Per Week

- 7-8 Months

- Standard Packaging

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Asia, Central America

- North India, South India, Central India, West India, East India

Product Description

Our organization takes immense pride in delivering a reliable and superior Hammer Mill to cater to the discerning requirements of our esteemed clientele. This mill undergoes meticulous craftsmanship at our state-of-the-art facilities, employing exceptional quality components and cutting-edge technology. It finds extensive application in the handling of materials such as limestone, coal, and hard rocks, rendering it highly sought-after within the market. Prior to its distribution, the Hammer Mill undergoes rigorous scrutiny across various quality parameters, ensuring impeccable performance. Leveraging our advanced manufacturing infrastructure, we possess the capability to fabricate, export, and market this exceptional product with utmost precision.

The following are the three main series of Ecoman hammer mills:

- 3000 Heavy Duty

- 4000 Medium Duty

- 1200 Light Duty

Hammer MillBenefits

- Effective size reduction of diverse materials.

- Capable of processing a wide range of materials, including rocks, coal, biofuels, and other compounds.

- Reversible hammers provide a longer lifespan without sacrificing quality or performance.

- The ability to change the rotating direction to optimize milling.

- Capability to generate a consistent particle size distribution.

Hammer Mill Technical Specification:

|

Capacity |

1000 TPH |

|

Material |

Mild Steel |

|

Brand |

Ecoman |

|

Width |

2200 mm |

|

Frequency |

50 Hz |

|

Phase |

3 Phase |

|

Voltage |

280 V |

|

Model No |

1200 Light Duty |

Our Best-Served Industries

AnimalTankage,Biomass & Biofuels, Coal, Bagasse, Limestone, Corn Stalks, Wood, Bran, Barley Shorts, Feed, Cocoa Shells, Crab, Clam & Oyster Shells, Grains, Wheat, Gelatin, Fish Meal, Meat, Scraps, Gypsum, Salt Cake, Oats, Soy Bean Expeller Cake, Corn, Hops, Steamed Bone, etc..

Download Brochure

Hammer MillFAQs

What is the purpose of a hammer mill?

A hammer mill is a mill that uses reversible hammers to pulverize or crush materials such as rocks, coal, or biomass. It is intended to offer effective and diverse size reduction capabilities

What is the operation of a hammer mill?

The impact of hammers striking the material within the crushing chamber powers a hammer mill. The hammers revolve and provide high-velocity blows on the material, breaking it down into smaller particles. A reversible hammer mill has hammers that may be reversed or flipped, allowing for longer hammer life and increased performance.

What are the essential parts of a hammer mill?

A rotor with reversible hammers, a crushing chamber, a feed inlet, a discharge outlet, a driving system, and a control panel are the essential components of a reversible hammer mill.

What materials may be processed by a hammer mill?

Coal, limestone, gypsum, clay, shale, and different biomass sources may all be processed using a hammer mill.

Can a hammer mill process huge materials?

The ability of a reversible hammer mill to handle large-sized materials is determined by the mills unique design and capacity. hammer mills are often used for medium to fine grinding or crushing of bigger materials.

Advanced Efficiency and Performance

Experience unparalleled productivity with our hammer mill, designed for industrial-scale output and operational efficiency. The machines high throughput, lower noise levels, and reduced energy demands ensure smooth, cost-effective processing. Leveraging modern engineering principles, it delivers consistent particle size while maintaining eco-friendly standards, making it suitable for a variety of raw materials and applications.

Eco-Friendly and Low Noise Operation

Our hammer mill champions sustainability with minimized emissions and a quieter operational profile. Its innovative construction reduces noise pollution and energy consumption without sacrificing performance. Ideal for workplace environments that prioritize employee well-being and environmental impact, the hammer mill offers both power and responsibility in one expertly crafted machine.

FAQs of Hammer Mill:

Q: How does the Hammer Mill achieve high performance with low energy consumption?

A: The hammer mill utilizes advanced engineering and robust components to maximize efficiency while minimizing energy usage. Its automatic operation, combined with precision design, ensures optimal throughput of up to 1000 T/hr without excessive power draw, making it both powerful and energy-efficient.Q: What are the primary industrial applications of this Hammer Mill?

A: This hammer mill is suitable for a wide range of industrial applications, such as size reduction of various raw materials in agriculture, food processing, chemical, and mineral industries. Its general-purpose design makes it versatile for different industrial workflows across India.Q: When is maintenance required for the Hammer Mill, and what warranty is provided?

A: Routine maintenance should be performed periodically based on usage intensity and manufacturer recommendations. A standard warranty is provided by the supplier or manufacturer, covering potential manufacturing defects and ensuring peace of mind for users.Q: Where can I purchase the Hammer Mill in India?

A: The hammer mill is available throughout India from multiple sources, including authorized dealers, distributors, exporters, fabricators, manufacturers, producers, service providers, suppliers, and wholesalers. This widespread network guarantees easy access and support.Q: What benefits does the eco-friendly feature of this Hammer Mill offer?

A: The eco-friendly design reduces environmental impact by minimizing noise and lowering energy consumption. This not only supports environmental sustainability but also helps industries comply with regulatory standards and reduce operational costs.Q: How is the Hammer Mill operated and what voltage is required?

A: The hammer mill operates automatically for user convenience and requires a 280-volt power supply. Its fully automated system ensures consistent operation, reducing manual intervention and boosting productivity.Q: What is the typical usage process for this Hammer Mill in an industrial setting?

A: In industrial settings, raw materials are loaded into the hammer mill, which then processes them efficiently under automated control. Outputs are consistently sized and ready for the next step in production, ensuring streamlined workflow and reliable results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese